14 extended z the phase-field GB model by taking into account the non-Fickian Li diffusion in two-dimensional polycrystalline microstructures, and considering the crystallographic anisotropy of the self-diffusion coefficient of Li and the elastic stress field associated with Li intercalation. They showed that the apparent Li diffusivity is sensitive to the diffusivity of the grain boundaries, the spatial distribution of the crystal orientation for each grain, and the grain size. In their model, a two-dimensional polycrys-talline microstructure was used, where a crystallographic orientation was randomly allocated to each crystal grain. 5 developed a PFM to evaluate the relation between the realistic polycrystalline LiCoO 2 microstructure and the apparent Li diffusion coefficient. In recent years, there has been a tremendous increase in the number of studies dedicated to the investigation of battery electrodes by PFM 5,14-18 however, only a few of them are dealing with the GB structures of electrodes. grain boundary) order parameters in combined simulation approach to represent diffusion processes and the change of microstructures, PFM provides a valuable tool for predicting the performance change of alternative electrode architec-tures and complex evolution of phases. intercalated ions concentration) and non-conserved (e.g. Among many techniques to model GB formation and their evolution upon ions intercalation, PFM is one of the most promising methods. The results provide new quantitative insights concerning performance loss of thin film metal alloy batteries. This paper develops a generalized phase-field model (PFM) that enables the incorporation of detailed grains/grain boundaries ions diffusion processes coupled with stress field. Applying that understanding is important to the design, optimization, and fabrication of certain grain microstructures as a means to achieve high capacity and long lasting battery performance. 6-8 Thus, there is certainly a need to better understand the kinetics of Na intercalation and the associated stress generation in grain structured electrodes.

5 Indeed, the prior transmission electron microscopy (TEM) studies have shown that metal alloy electrodes undergo fracturing as a result of significant stress buildup after cycling. 1-3 Although the grain boundary (GB) in thin film metal alloys provides a low energy barrier ions intercalations path, 4 it also contributes to dele-terious internal resistant growth and capacity loss due to diffusion induced stress buildup which could lead to grain damage.

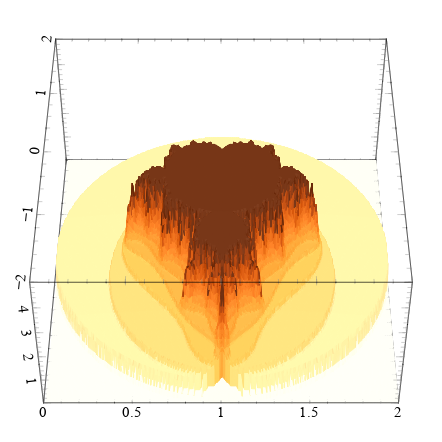

The partial differential equations, representing ions concentration progress and the GB evolution, are solved computationally using the finite element method. The phase-field GB model is used to generate thin film grain structures and subsequently to study their evolution during the ions diffusion.

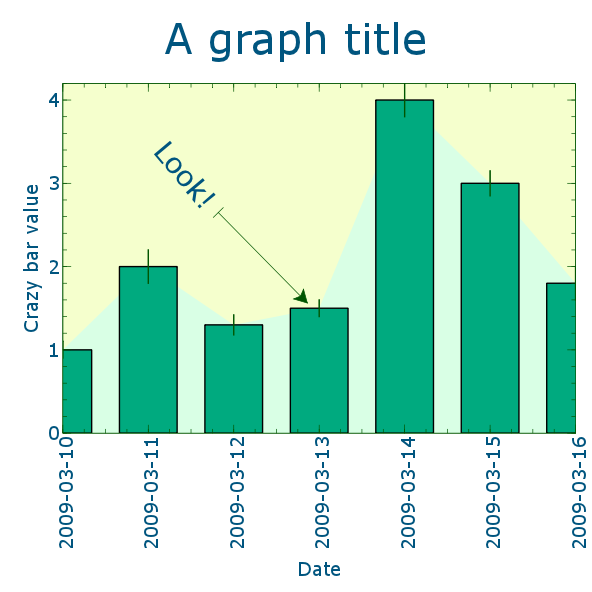

VEUSZ PLOT FREE

Electrochemical free energy functions, considering ions diffusion within the grains and the grain boundary (GB), along with the elastic stress field associated with ions intercalation, are considered.

Herein, we present a phase-field model (PFM) representing ions diffusion/intercalation into polycrystalline battery electrodes and its coupling to mechanics equations.

0 kommentar(er)

0 kommentar(er)